Project

A medical component manufacturing facility approached Spiros with a project involving building a highly precise wire form spring for a medical device used for tumor removal.

Challenge

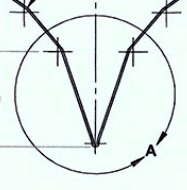

90% of the component can be formed off of a CNC wire forming machine, with the exception of the 0.040” R tip geometry and transition legs.

Action Steps

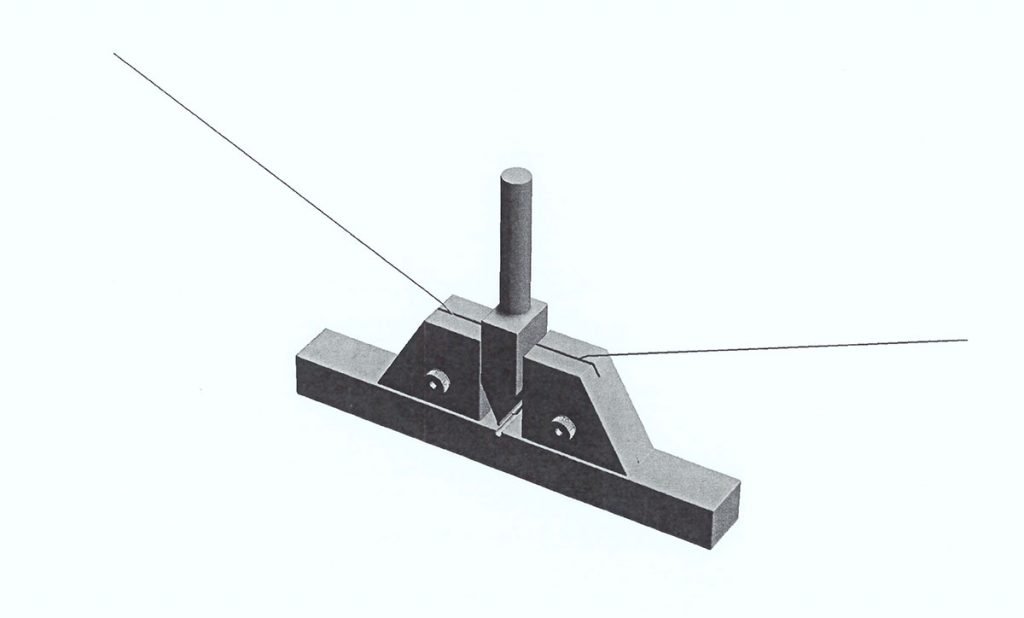

Spiros built specialty tooling to secondary the detail A spec of 0.040” R.

Result

After working closely with the customer’s engineering group and the second revision of tooling, the end product was achieved.